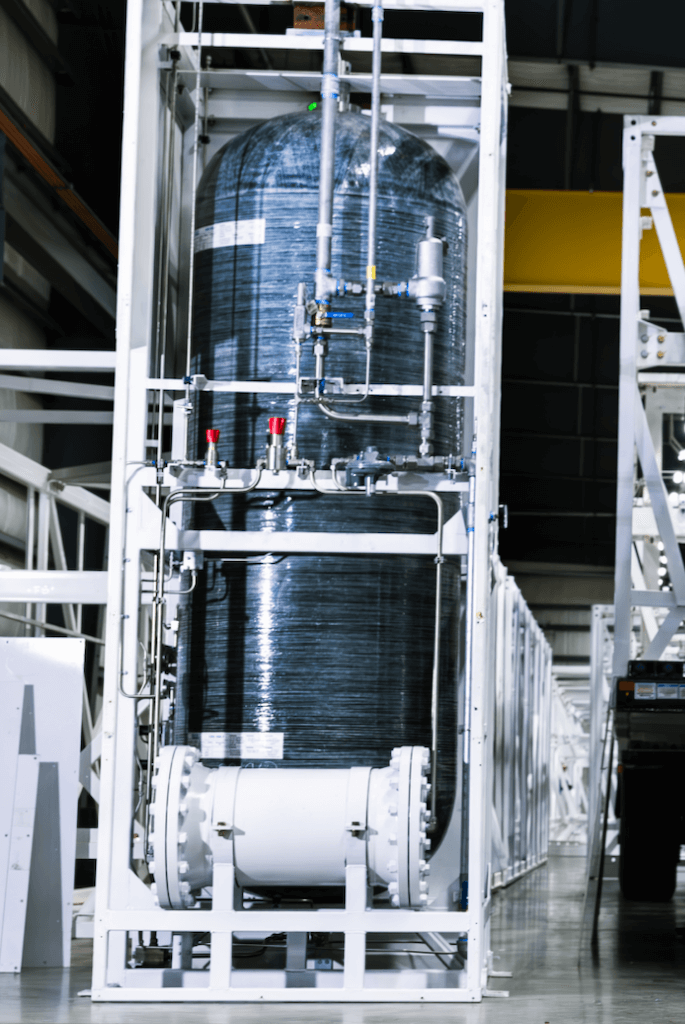

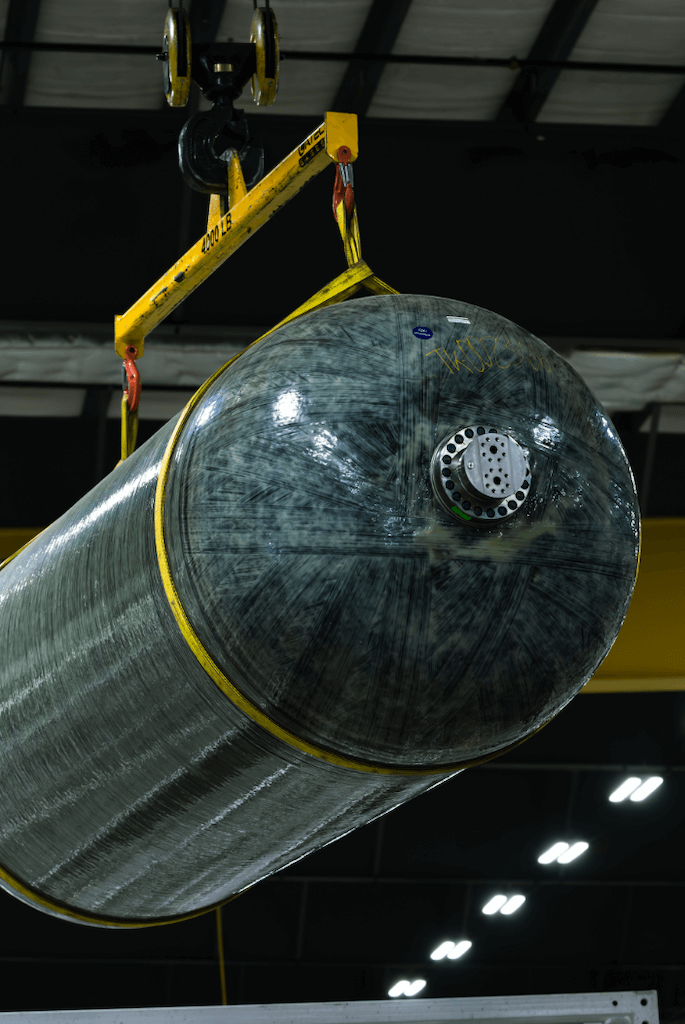

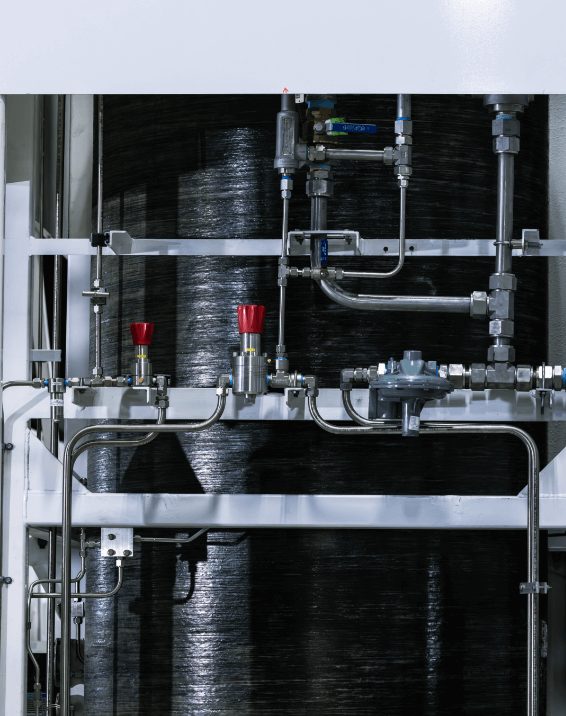

HYDRIA’s Type IV cylinders redefine the boundaries of high-pressure gas storage. With an unparalleled 48-inch diameter—the largest in the industry—and crafted from the world’s strongest carbon fiber, these cylinders exemplify the pinnacle of engineering excellence. Their advanced roto-molded plastic liner creates a seamless, corrosion-resistant barrier – safeguarding gas purity – while offering unmatched durability. This superior strength-to-weight design enables higher storage capacities, ensuring lighter, more resilient solutions compared to traditional steel cylinders. HYDRIA’s commitment to pushing limits ensures that every Type IV cylinder not only meets but exceeds the most stringent safety standards, delivering unparalleled performance and efficiency across a wide array of applications.

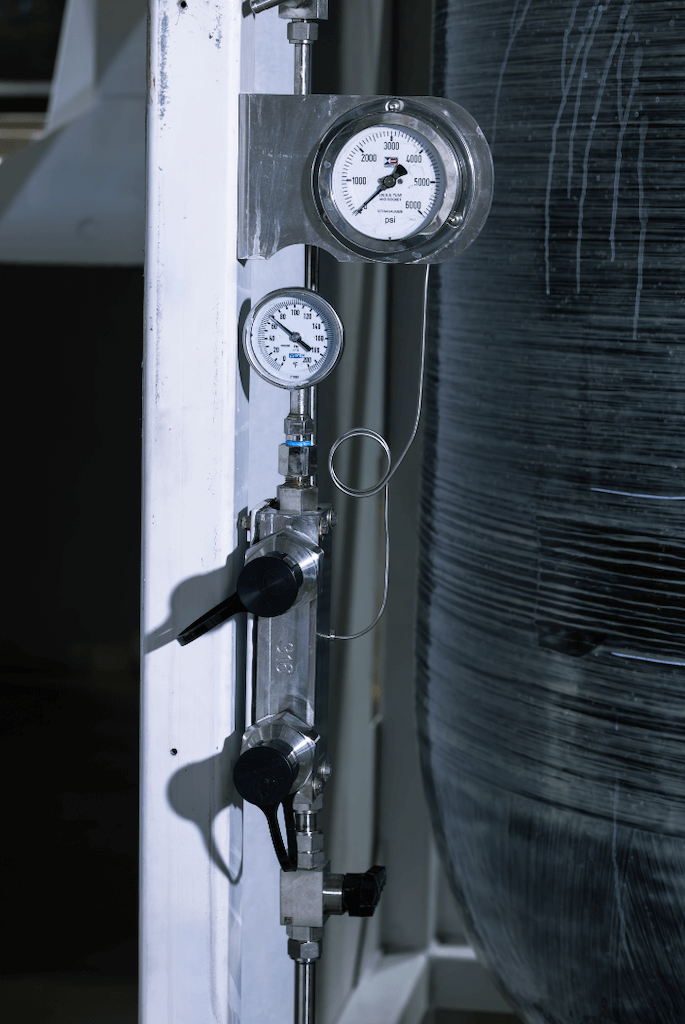

Precision-engineered for optimized gas storage and transportation, the Kelley Gas Transportation Module (KGTM) Type II cylinder marries the ruggedness of steel with the innovation of composite materials. Its fiberglass-reinforced steel liner operates at an optimal 3,250 psi, providing a perfect balance of capacity, safety, and efficiency for industrial gas applications. A testament to HYDRIA’s leadership in design and reliability, the KGTM Type II cylinder represents the ideal choice for enterprises prioritizing uncompromising performance and safety compliance for transporting compressed gases such as CNG, hydrogen, and helium.

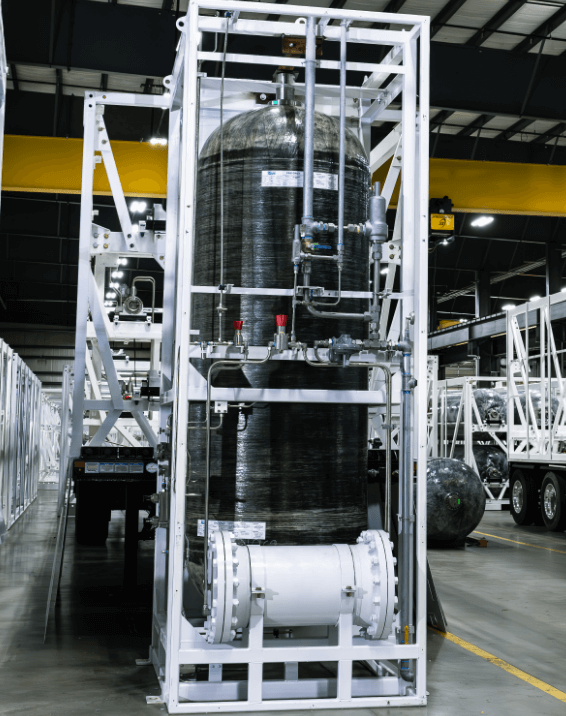

HYDRIA’s Vault storage systems provide advanced solutions for high-pressure gas storage, accommodating hydrogen, compressed natural gas (CNG), renewable natural gas (RNG), and helium. Featuring industry-leading 48-inch diameter Type IV cylinders—the largest available—these systems maximize storage capacity within a compact footprint. Constructed with the strongest carbon fiber on the market, the cylinders ensure exceptional durability and safety. The innovative design includes a roto-molded plastic liner that maintains gas purity and resists corrosion. Vault systems are versatile, allowing for vertical or horizontal configurations and stackable arrangements to optimize space utilization. This flexibility makes them ideal for various applications, including industrial gas storage and energy infrastructure projects. By integrating HYDRIA’s cutting-edge Vault storage systems, organizations can achieve reliable, efficient, and safe gas storage solutions tailored to their specific needs.

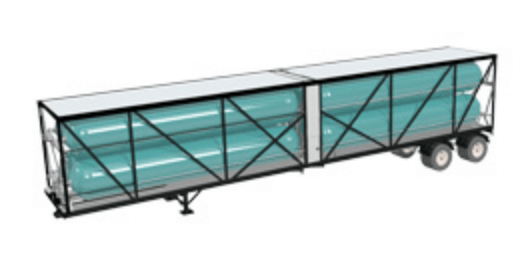

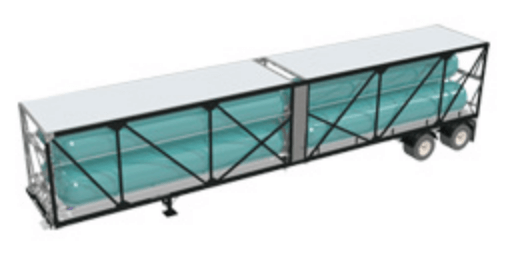

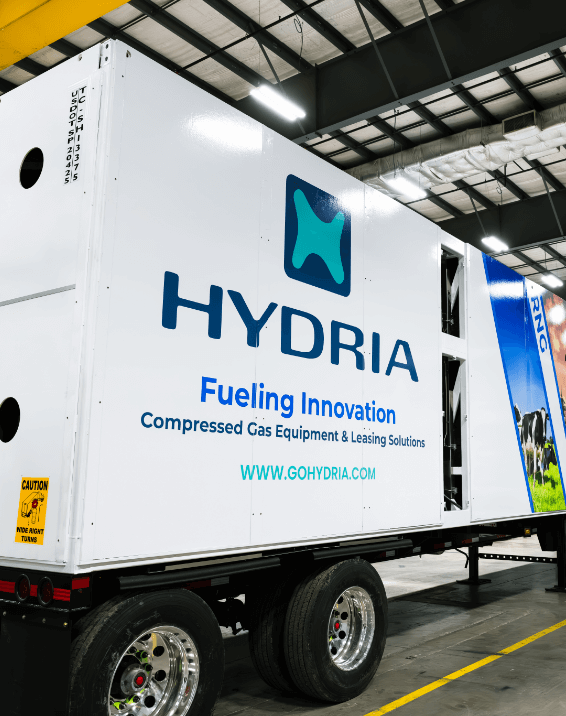

HYDRIA’s gas transport trailers are engineered to set the highest standards for safety, performance, and operational efficiency in high-pressure gas transportation. Key features include:

Equipped with the largest 48-inch diameter Type IV cylinders, reinforced with the highest tensile-strength carbon fiber and a solid roto-molded polymer liner, ensuring gas purity and structural integrity. The design also includes the largest cylinder neck on the market, contributing to durability and safe operation.

HYDRIA’s trailers boast a reinforced chassis with the lowest center of gravity, enhancing stability during transport. An air ride suspension system and rollover stability features come standard, ensuring a smooth ride and increased safety.

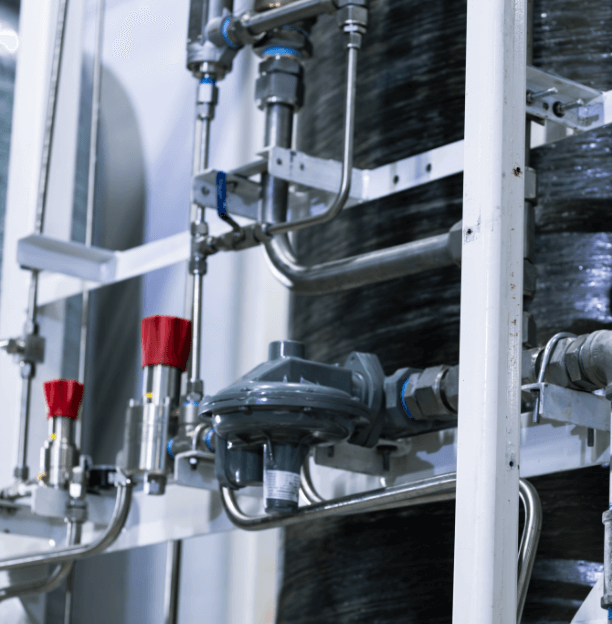

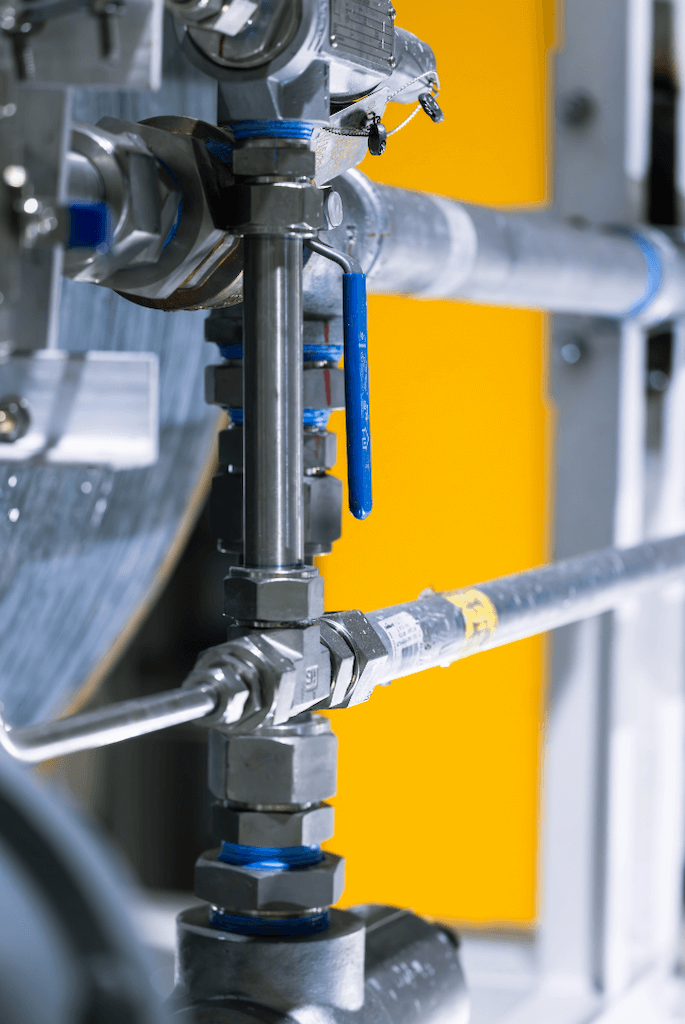

Each trailer includes advanced features for ease of use and safety, such as fast-fill technology, gas or air-actuated valves, and customizable control panels with rear or side load/unload options. Additionally, telemetry integration provides remote monitoring, enhancing operational control.

HYDRIA trailers prioritize safety with multiple layers of protection, including strategically placed pressure relief devices (PRDs) that activate in high-heat scenarios, a break-interlock system to prevent unintentional movement during loading/unloading, and leak detection features. Additionally, enclosed plumbing and central control panels reduce risk in case of a rear-end impact.

To ensure safe and optimal use, HYDRIA provides a comprehensive operational demonstration and training for clients prior to delivery, along with a detailed operating manual for continued guidance.

HYDRIA’s commitment to innovation and safety ensures that these trailers offer a secure, efficient, and scalable solution for transporting gases like hydrogen, CNG, RNG, and helium.

All trailer options are engineered with high-pressure capabilities (up to 4,000 psi), fast fill technology, telemetry for remote monitoring, and advanced safety features, making them adaptable for a wide range of applications and gas types.

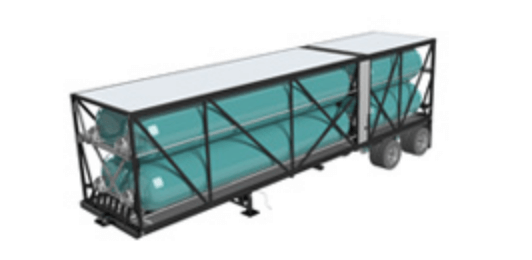

The KGTM Type II trailer from Kelley Gas Transportation Module (KGTM) is designed for efficient, high-volume gas transportation. Key features include:

Equipped with 9 steel cylinders, hoop-wrapped with resin-infused fiberglass, the KGTM trailer combines the strength of steel with the lightweight benefits of composite materials. Each cylinder delivers 13,734 cubic feet of compressed natural gas (CNG) at 3,250 psig, while the entire trailer provides a substantial capacity of 123,601 cubic feet

Constructed to meet US DOT SP 14867 standards, the KGTM trailer ensures regulatory compliance and reliable performance under high-pressure conditions.

Suitable for transporting various gases, including methane, natural gas, helium, hydrogen, nitrogen, ethane, and compressed air, making the trailer highly adaptable for diverse industrial needs.

With a tare weight of 36,500 lbs and compact dimensions (height: 8’-6”, length: 19’-10.5”, width: 8’), the trailer is designed for balanced weight distribution and easy maneuverability.

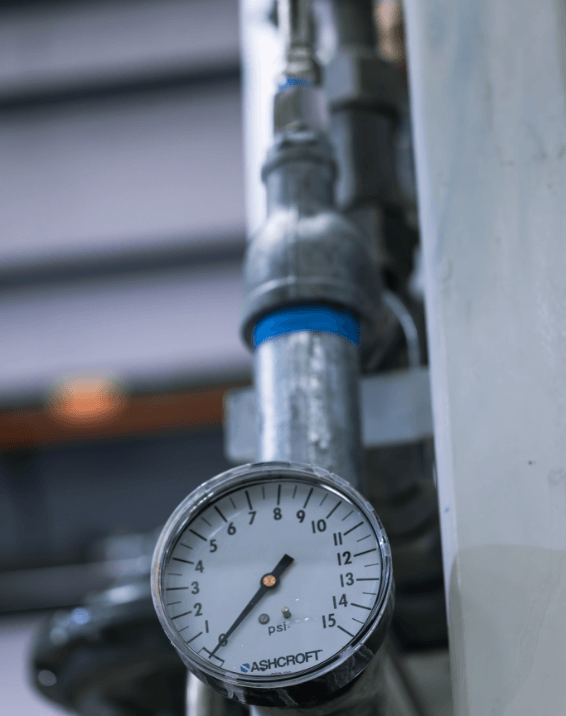

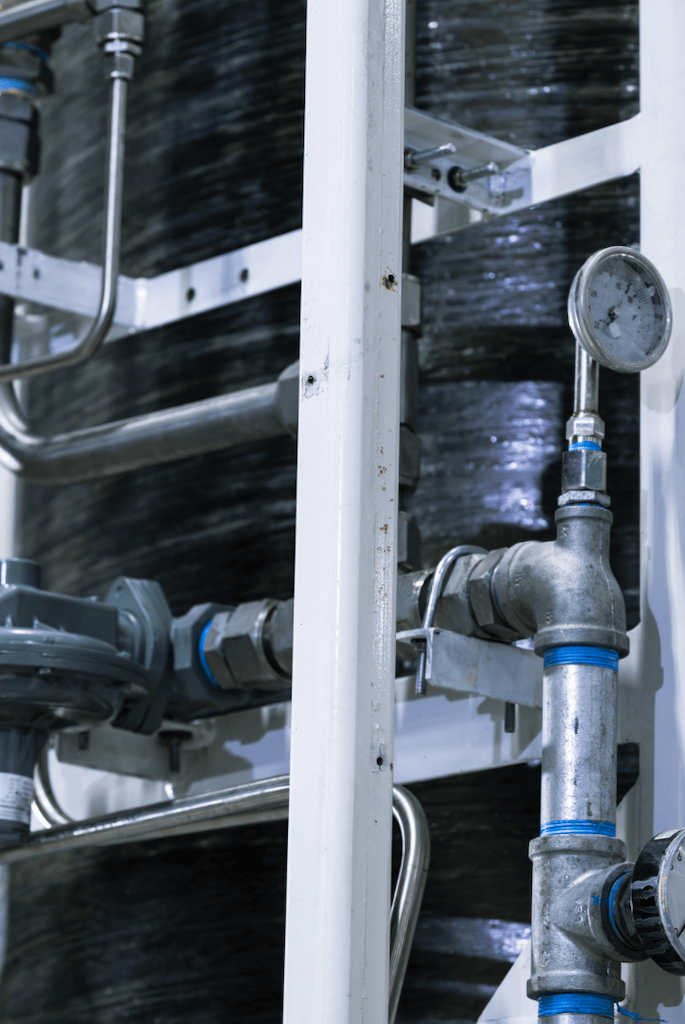

The trailer features a stainless steel manifold with a 0.91” bore and venting valve for efficient filling and discharging. Each cylinder is connected to the manifold with durable stainless steel tubing, enhancing safety and operational ease.

A 1” FNPT fill and discharge connection with an optional second connection point offers operational flexibility, enabling quick and safe gas transfers.

The KGTM Type II trailer delivers high-performance gas transport solutions that are safe, versatile, and built to last, making it ideal for industrial and energy sector applications.

HYDRIA’s gas technologies, enhanced with Vault Storage Solutions and Type IV and Type II Trailers, offer a highly resilient and adaptable energy system that ensures an uninterrupted supply with seamless integration into existing gas infrastructure and virtual pipeline capabilities. This design provides a flexible solution to meet diverse energy demands, delivering continuous reliability even in locations without direct pipeline access.

Vault storage offers expanded, on-site fuel reserves, providing reliable buffer against fluctuations in demand and potential supply disruptions.

HYDRIA’s mobile Type IV and Type II Trailers offer flexible storage and transport options, ideal for campuses needing supplementary capacity or emergency support.

With Vault storage and Type IV and Type II Trailers, HYDRIA’s solutions achieve over 99.99% uptime, delivering a consistent CNG supply supported by robust redundancy and high availability.

The system is designed to detect pressure drops and respond instantly, leveraging high-pressure storage at 4,000 psi for rapid supply replenishment within 30 seconds.

All installations meet rigorous safety standards, including gas detection, fire and lightning protection, and security features. HYDRIA also ensures full regulatory compliance, handling permits and periodic inspections as part of ongoing support.

With a 20-year operational commitment, HYDRIA provides comprehensive maintenance, including predictive maintenance plans, spare parts, and dedicated support to maintain optimal performance.

HYDRIA’s gas technologies for Microgrid Applications provide a robust and adaptable energy platform designed to enhance microgrid reliability, speed to market, and autonomy from centralized electrical grids. Leveraging Vault Storage Solutions, Type IV and Type II Trailers, and virtual pipeline capabilities, HYDRIA supports a decentralized energy approach that prioritizes rapid deployment, resilience, and energy independence.

HYDRIA’s high-capacity Vault storage offers a stable, on-site energy reserve, empowering microgrids to manage peak loads and adapt to fluctuating demand.

HYDRIA’s trailers provide mobile, scalable fuel storage, ideal for microgrids requiring adaptable energy supply or supplemental support in remote locations.

HYDRIA’s virtual pipeline approach eliminates the need for permanent pipeline infrastructure, enhancing flexibility and resilience.

HYDRIA’s technologies enable microgrids to become operational faster than centralized grid installations, achieving over 99.99% uptime for consistent energy delivery.

High-pressure storage and virtual pipeline capabilities enable instant response to demand fluctuations, ensuring seamless microgrid operation.

HYDRIA integrates advanced safety measures, including gas detection and fire protection, while managing permits and regulatory inspections to ensure compliance.

HYDRIA offers a 20-year maintenance plan, including predictive maintenance, spare parts, and dedicated support to keep systems operating at peak performance.